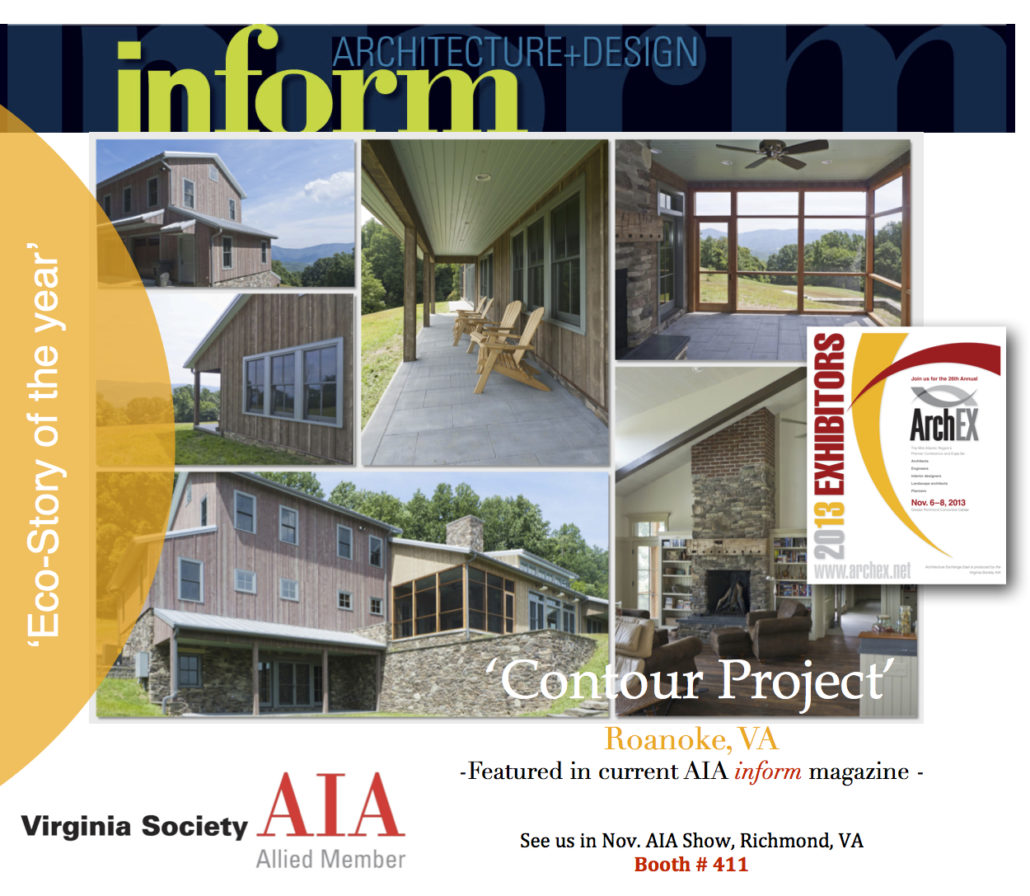

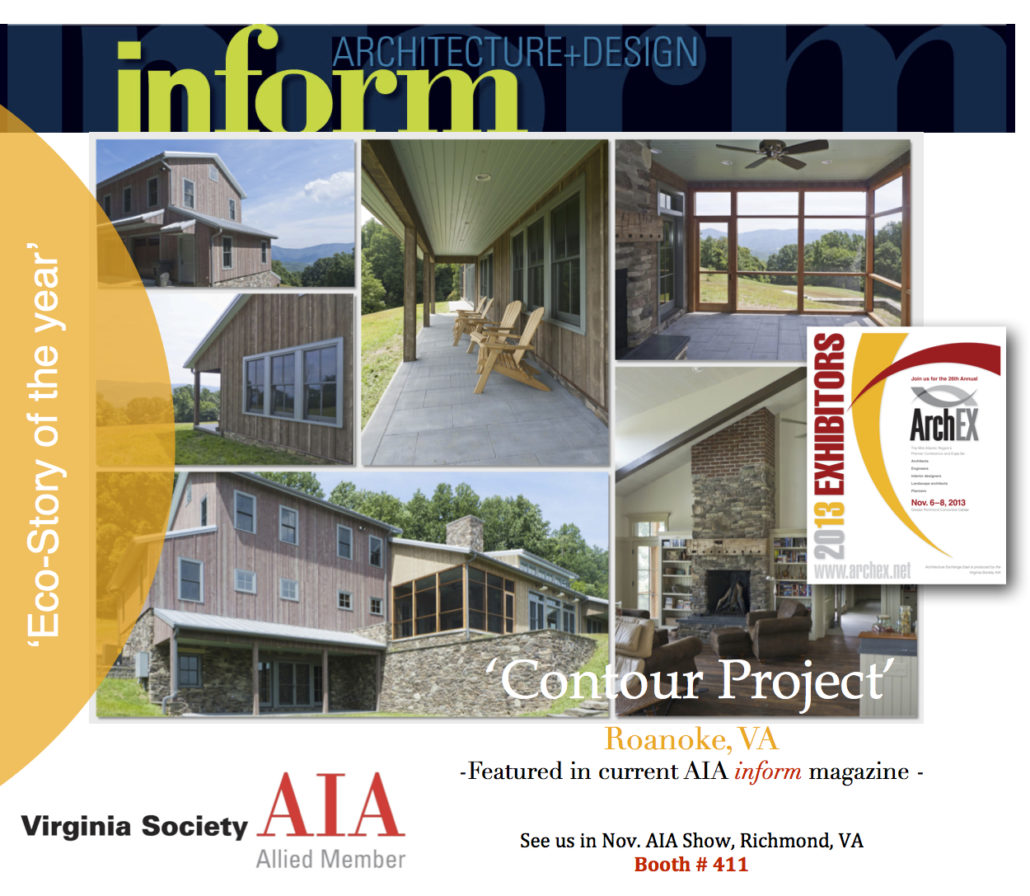

This home settles into the hillside to capture views without dominating its surroundings.

Photos by Architect Peter LaBau.

by Douglas Gordon, Hon. AIA

The Contours were starting a new chapter in their lives, retiring from California and wanting a place in the Virginia Piedmont where they could work; he could jam with his musician friends; they could entertain and be close yet visually separate from the neighboring communities, including nearby Roanoke; and their children had a commodious place to visit.

The existing early 1800s cabin on the property was inspirational, but not functional for their needs, recalls Peter LaBau, their regionally based architect. It wasn’t salvageable, “but did have exposed stone on the foundation and a rambling look with older and newer pieces joined, and that really moved them,” he says.

“They wanted a central core, as the original cabin had been, with a voluminous feel inside and appendages working off of that. She also liked the idea of blending in more contemporary flavors so that it wasn’t just a period knock-off.” Some of the new residents settling in the interior solution were a compartmentalization of spaces. His office is on the lower level and rather simple to accommodate his nocturnal work habits, and it is adjacent to his acoustically isolated music room. Her office and bedroom are directly above with breathtaking views of the Blue Ridge, owing to her love of day-lighted space. A berm separates the house visually from their nearest neighbor about a quarter of a mile away.

The house is situated on a modest plateau enlarged from the original hillside clearing. The approach is steep and winding, with the first element that comes into view being a stabilized outbuilding, which serves as much as a folly as a storage area, LaBau says. The drive ascends just beyond the house to an overlooking garage connected to the house via a pergola. The home’s footprint—including a modest landscaped yard (more of a 45-degree sloped rock garden)—takes up only a modest amount of the couple’s hillside forest acreage. Boulders and large rocks salvaged from the site became recreated outcroppings.

A rustic exterior with contemporary detailing hints at the comfortable and well-appointed interior amenities.

The building materials were also chosen to evoke a feeling of age and accumulation. The structure is timber with steel roof spans, and the look of structural stone is created from a cultured stone exterior finish that came in at $3 a foot. “This stuff gets better all the time,” LaBau extolled. “And we set it without grout so that it looks dry laid.”

The timber frame was pre-manufactured by Connor Homes, whose owner LaBau knew when he worked in New England. Shipping to Virginia added embodied waste energy, but otherwise the materials are sustainably harvested locally to the Connor factory. Their waste factor is 7 percent that of stick-built framing, the lumber is superb, and they deliver factory efficiency, LaBau explains.

Another major factor in making the home appear as if it had evolved over generations was the look of the exterior siding. “When Erin first came to me, she brought photographs of Western structures with the once-painted-now-faded look, which they really wanted,” LaBau says. “And it was totally fortuitous that a cold e-mail came to me soon after from Harvest Timber Specialty Products,” (which now works locally through the Eastern Seaboard distributor WT Fary Brothers, LLC out of Gloucester, VA).

“I wanted to use reclaimed materials on the cladding. But for an exterior application, I was really reluctant to use something that wouldn’t last. “The siding from Harvest Timber Specialty Products, though, is harvested from beetle-killed trees, which they cut before it has deteriorated. So instead of fueling the massive forest fires we’ve been seeing out West, this timber sequesters that accumulated carbon. They mill it and give it a textured surface and treat it so that the wood can be re-coated in the future and will last for many years. We chose three different colors for each of the separate building sections to achieve the look the client wanted.”

For more information contact:

Glen Ehrhardt, Business Development

PO Box 59 Lakebay, WA 98349

t. 253.884.6255

e. glen@harvest-timber.com